Freeze Frame

The evening of Jan. 31, 1949 in Waco, saw an otherwise unremarkable evening take a turn when temperatures hit minus 5 Farenheit – minus 20 Celsius – a measure that still stands as the coldest on record for the city. Students working in the lab of Stephen T. McClain, PhD. professor and graduate program director of mechanical engineering in Baylor’s School of Engineering and Computer Science, often find themselves collecting data from an even colder environment, measuring frost formations on aircraft surfaces using a wing box lab that can reach minus 25 Celsius through a process known as cold soaking.

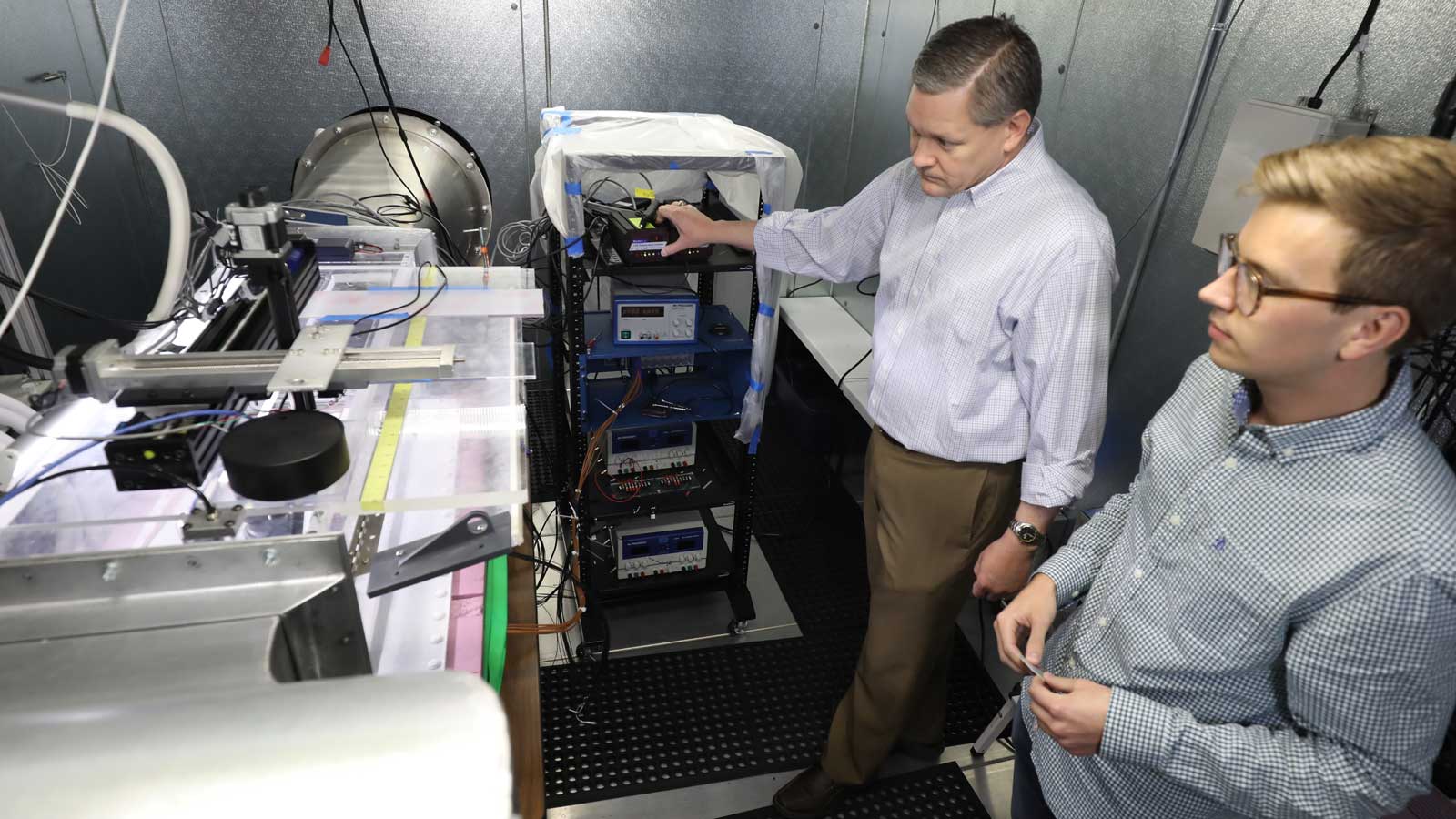

“We basically have a big model of an aircraft wing fuel tank. We chill it down to minus 25 Celsius and then pull the foam off and let frost grow,” McClain said. “It’s really hard to make ice in Texas, but we can do it, and it takes a lot of work to get down to those temperatures.”

Located in the 300,000-square-foot Baylor Research and Innovation Collaborative (BRIC) complex, McClain’s lab conducts research on basic fluid mechanics and heat transfer, primarily related to aerospace or, as he simplifies it, “watching frost grow and making clouds.”

In reality, his research is addressing a complex matter of safety that modern airlines and aircraft face on a near daily basis.

In reality, his research is addressing a complex matter of safety that modern airlines and aircraft face on a near daily basis.

“The Federal Aviation Administration [FAA] has a mandate that you cannot take off if you have any sort of contamination on the wings, but airlines or certain shipping carriers demand or desire very quick turnaround times,” McClain said. “In other words, you get to your destination, move everybody or all the cargo off, get more people or cargo back on, and take off.”

Of particular concern to the FAA is the issue of frost build up on the aircraft wings after landing.

“The aircraft surfaces can be really cold after being up at 30,000 feet — it’s minus 50 Celsius temperatures,” McClain said. “This project is specifically about aerodynamics related to flight safety. Manufacturers can apply for an exemption to take off with some frost, but they must have substantial experimental data and a model to demonstrate that their aircraft can take off without being impacted by frost.”

McClain has a background in studying flow over rough surfaces, which is fundamentally what his study of frost is. For manufacturers like Boeing, the certification analysis in their exemption application comes down to evaluating air flow over the surface of the frost on the aircraft wings.

“My original research associated with my PhD. was related to gas turbine roughness on blades or what happens inside the gas turbine engine,” McClain said. “My connection to this project actually comes through a long history in the aircraft icing world — a history of research dating back to 2004 with the icing branch at NASA Glenn.”

A summer stint as a NASA Summer Faculty Fellow in the Icing Research Branch at the NASA Glenn Research Center in Cleveland, Ohio, laid the groundwork for McClain’s emergence as an industry expert in ice build up on aircraft surfaces.

His prior experience evaluating gas turbine heat transfer made icing a natural next step in his research endeavors.

“A turbine blade is just a highly curved airfoil or a wing,” McClain said. “When you have ice accreting on the aircraft surface, it forms roughness. It’s almost identical except for the fact that the heat transfer is going in the opposite directions. It’s a very similar situation in terms of flow over a rough airfoil.”

In his early research in icing at NASA Glenn, McClain joined a collaborative effort to develop a tool for measuring ice roughness on airfoils.

“[Measuring] is actually one of the fundamental or most difficult things that we have to do with frost because frost itself is ice,” McClain explained. “It’s clear, it’s brittle. Most other times, surface roughness is measured with something that looks like a record player. It has a stylus that tracks the surface. If you try to do that with frost, the stylus is just going to dig into the frost and drag it along. You’re not going to get measurements of the frost dendrites and the feathers that stick up into the flow stream.”

Using a similar approach as modern day aerial surveying mechanisms used by drones to map and take measurements of topography, McClain’s team developed a method of photogrammetry to measure and map frost formations. A small camera on a stage moves back and forth in a pattern, using similar algorithms as the surveying drones to measure frost surface roughness.

With the FAA and NASA keenly interested in his work, McClain has found a natural partner in his ongoing research efforts in Dennis O’Neal, PhD. dean of Baylor’s School of Engineering and Computer Science, who happens to also be an expert in frost modeling. Facing a critical safety concern in the aviation industy, the two Baylor experts have found an opportunity at the intersection of their highly-specialized respective research areas.

Although his speciality has trended toward ground icing on aircraft, McClain maintains a very broad laboratory at the BRIC that includes specialized wind tunnels and high powered lasers.

“We’re using the wind tunnels to develop sensors that measure how much water is captured along the airfoil surface as it flies through a cloud,” McClain said. “We’re looking at how these sensors can be used to better understand icing and cloud physics.”

The laser diagnostics with high-powered lasers provide a more fundamental or physics teaching moment, allowing a full spectrum from the foundational knowledge gathering up to the highly applied approach working with ice accretions.

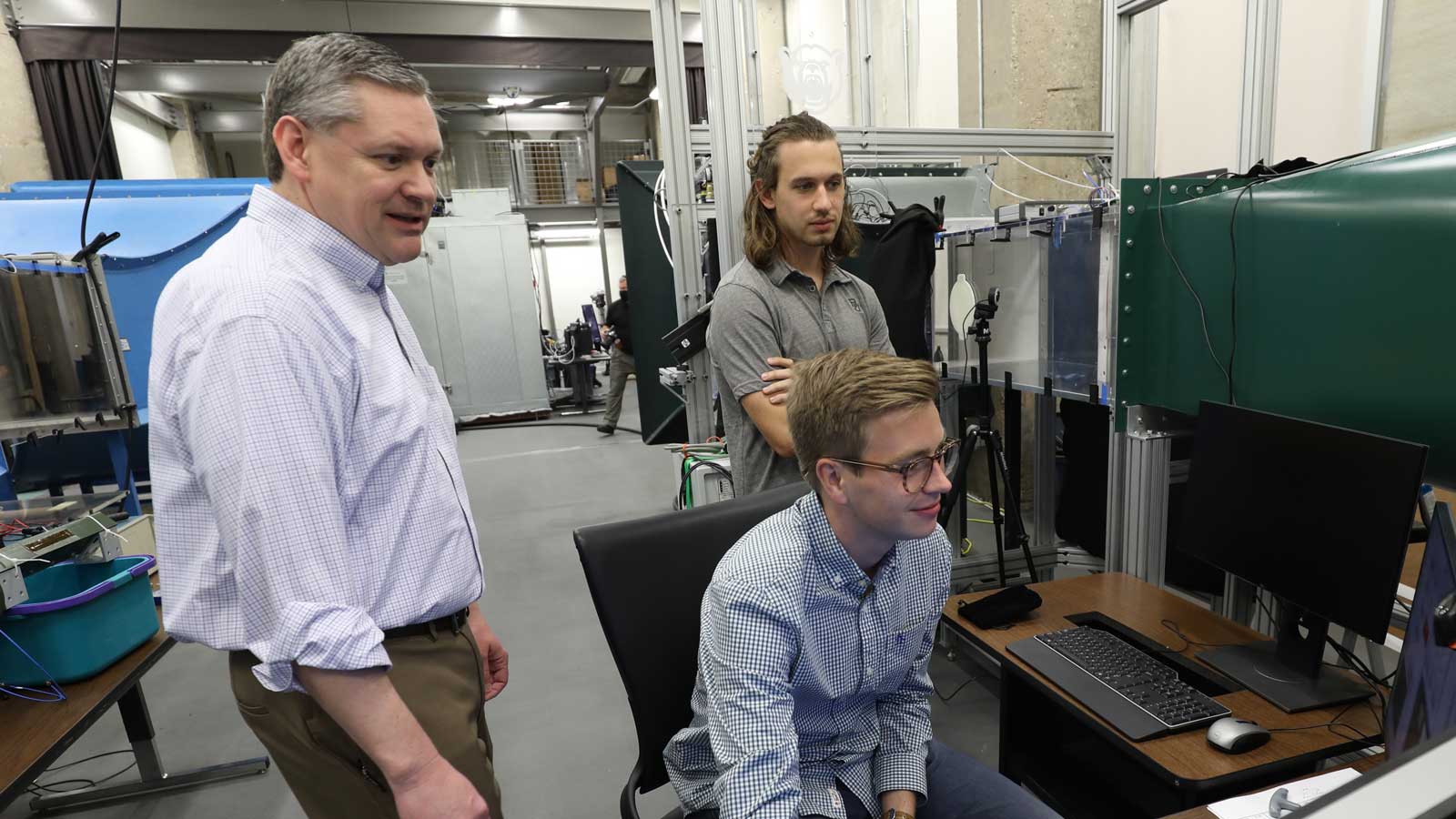

As Baylor continues to approach R1 status as a top-tier research institution, students have become an integral part of McClain’s lab work.

“My selling point for students is always going to be, ‘If you want to know what a real research in a entrepreneurial lab is going to be like, go into a university research lab,’” McClain said. “If you think about how professors operate, we pretty much operate like small business owners. We’re taking university resources and finding the best mechanisms for what interests the community, whether that’s government, industry, corporations, other research organizations – we look at what interests them the most to bring that work and that research back to the university.”

In what can be the very competitive arena of academic research, McClain has found a home at Baylor, appreciating an atmosphere that allows for constructive collaboration and a unified faculty that tries to work toward the same mission.

“We enjoy a very cohesive and caring Mechanical Engineering department, School of Engineering and Computer Science, and University as a whole,” McClain said. “We’re a unified group, and it’s great to work in that type of environment because we can still have disagreements, but everybody understands that we have a bigger purpose. That’s amazing, and it’s not common – I think that’s one of the best things about Baylor.”